Mechanical Systems

IR Thermography of Mechanical Systems:

IR inspection along with Vibration Analysis or Ultrasound Analysis is the complete tool for carrying out predictive maintenance of below mentioned machines/systems. Few of the major anomalies include rubbing of parts, overheating, jammed parts etc. In compressor, the compressor head temperature is major issue. It is always easy to inspect condition of number of bearings on kilometer long conveyers with the help of IR Thermography.

IR inspection along with Vibration Analysis or Ultrasound Analysis is the complete tool for carrying out predictive maintenance of below mentioned machines/systems. Few of the major anomalies include rubbing of parts, overheating, jammed parts etc. In compressor, the compressor head temperature is major issue. It is always easy to inspect condition of number of bearings on kilometer long conveyers with the help of IR Thermography.

-

Gear Box

-

Bearings

-

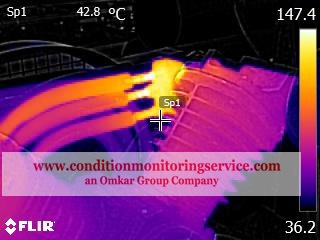

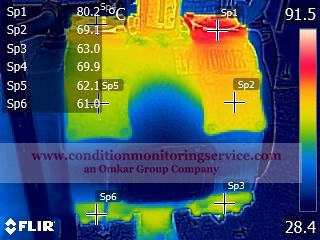

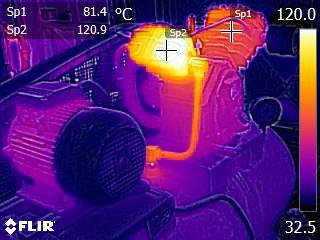

Compressors & Intercoolers: In compressors, Thermography helps in determining Overheated bearings, Compressor discharge Temperature, High Oil Temp, Broken or Defective Valves or rings etc.

-

Compressors

|

|

Pipes Heated Up

|

|

One of the head is over-heated

|

|

|

|

One of the head Overheated

-

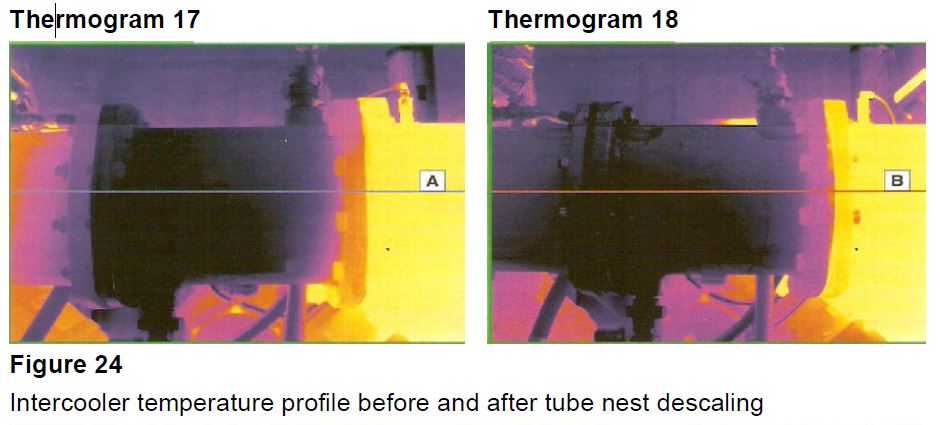

Intercoolers: Clogged Intercooler

Intercooler is LEFT thermogram shows clogging and the RIGHT thermogram is after Tubes Descaling

-

Pumps

|

|

Only One Pump is under operation, Motor is hot and pumping cold fluid

-

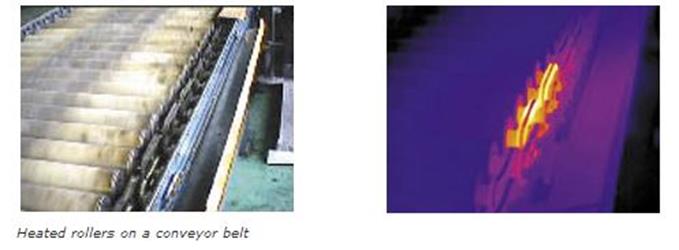

Conveyers Bearings

Thermogram illustrate failed rollers on Conveyor Belt

Thermogram locating overheated roller bearing on kilometers long conveyor

-

Internal Combustion Engines: Valves or injectors Malfunction, Blocked Radiator Tube, and Oil Coolers

-

Mechanical Drive Turbines & Small Turbine Generators: High Lube Oil Temp, High Bearing Temp, Drain Valve Blockage, Steam Trap blockage, Faulty stop/control Valve Operations & Leaking Shaft Seals.

-

HVAC Plant

-

Refrigeration Plant

-

Drive Belts

-

Couplings