SSPN ReliabilityEdge Pvt Ltd

To know more about our services & learn condition monitoring techniques through our blogs, please visit our new website, www.edgereliability.com

Organic Maintenance 4.0

Like RCM, TPM, and BCM, ‘Organic Maintenance 4.0’ is a new concept in Maintenance Field.

Do you really ‘Maintain’ your machines? (Just think about the meaning of the word ‘Maintain’ then answer the question.) Most of the company doesn’t have planned maintenance but rather a ‘Maintenance Plan’. There should be a planned strategy to maintain machines and ‘Predictive – Preventive – Reactive’ maintenance should have been well planned. Yes, even one has to plan ‘Reactive Maintenance’. The Maintenance has reached ‘Prescriptive Maintenance’ today & we are still in preventive maintenance.

Organic Maintenance 4.0 is our innovation and blend of best’s in RCM, TPM, BCM maintenance strategies. You know about the industrial revolution 4.0. OM 4.0 is in line with Industry 4.0, IIoT & AI.

To read about it & know about it in details, please go to the link, Organic Maintenance Concept.

Prescriptive Maintenance (RxM) is a future of maintenance, the 4th generation (3rd Generation- Predictive Maintenance). Now the world is entering into Artificial Intelligence (AI), how can maintenance strategies lag behind? Prescriptive Maintenance is based on Artificial Intelligence (AI).

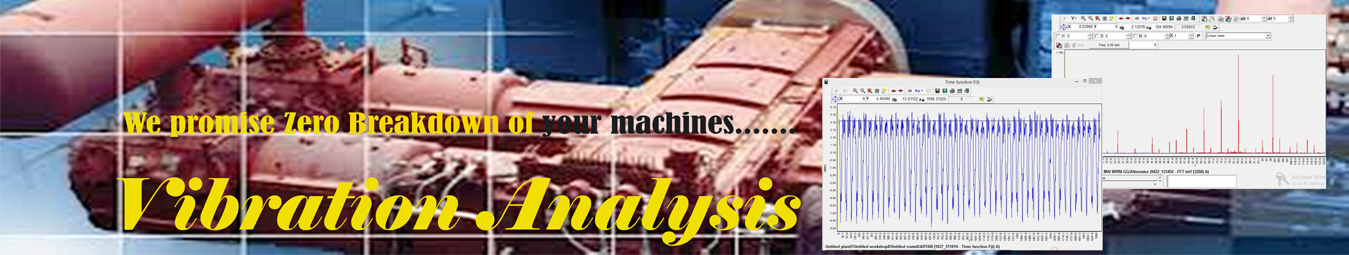

We have innovated, the best practices in Predictive Maintenance (PdM). The Vibration Analysis is not best tool of CM but it is the best tool of RCM. There are better & more effective and cheaper tools for condition monitoring of bearings. Our innovations in Predictive Maintenance (PdM) or Condition Based Maintenance (CBM) will help you in maintaining your plant & machinery more effectively in reality.

Organic Maintenance 4.0, means maintenance of literally everything in your company, including machines, equipment, and infrastructure. You point it and we will suggest you maintenance program. This way you can ‘maintain’ literally everything in your company. Please Click, Organic Maintenance Solutions

We are a company having experience of 35 years in maintenance/refurbishing of large/ extra large Electrical Rotating Machines, Pumps, Gear Boxes, and Compressors.

We have gone through almost every problem/ Catastrophic Failures concerned to above listed equipments and finally came to a conclusion that every of this failure would have been avoided and huge expenses on repair/ production losses could have been saved.

We found our customers weren't aware of new techniques of maintenance by which they could have saved heavy losses and achieve undisturbed continuous production. And we thought of providing ‘Proactive Maintenance’ solutions to our customers through our services.

Our other innovation in maintenance includes PIPF Curve. The PIPF curve explains OM 4.0 strategy. The maintenance starts right from Procurement of machines & the next step is Installation. If you procure machines suitable for your operating conditions, preventive maintenance & suitable for condition monitoring, the machine can give you longer operating life and lesser failures in its lifetime.

Other Services

-

Laser Alignment

plus -

In-Situ Balancing

plus -

Trainings

plus -

High Voltage Motors

plus -

Maintenance Consultancy

plus

Condition Monitoring System

Condition Monitoring System Offers Flawless Operation of Machines & Equipments, increases life, retains quality and restricts catastrophic failures.

Scheduled CBM

We will plan frequency of monitoring based on base data and visits will be scheduled and made to monitor condition of your machine. Analysis will be followed by every visit and reports will be submitted.

Base Data Generation

We inspect the given machine online with combination of NDT techniques and generate base data.

Analysis

Trend Analyst

Trend Analysis will be done based on CBM results and progressive condition of machine will be graphed.

Condition Monitoring

Provides multi-level views & access to your entire PdM Program across the enterprise.

Our Services

-

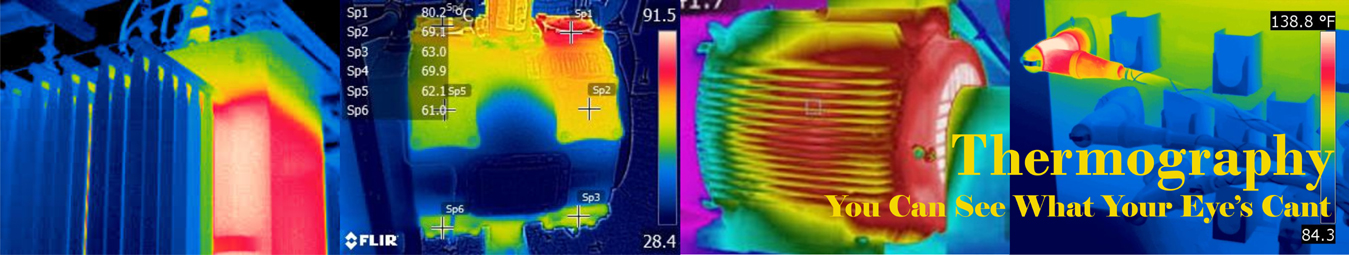

Thermography

We have managed the world's largest and longest running vibration analysis programs.

-

Vibration Analysis

We have managed the world's largest and longest running vibration analysis programs.

-

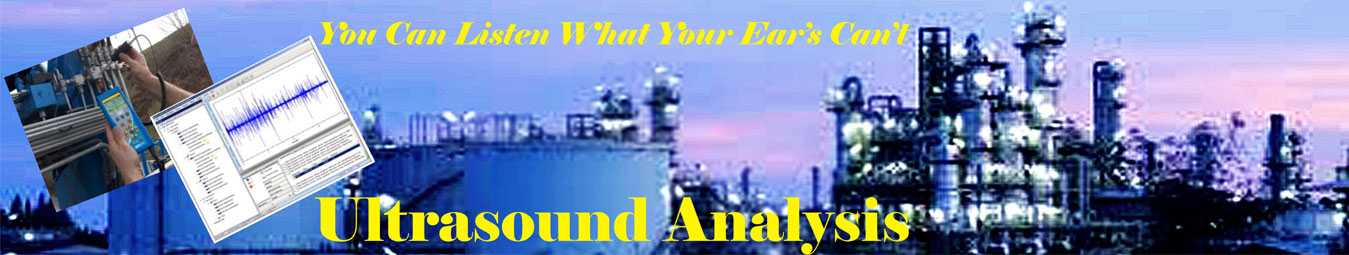

Ultrasound Analysis

We have managed the world's largest and longest running vibration analysis programs.

-

Condition Monitoring

We have managed the world's largest and longest running vibration analysis programs.

-

In-Situ Balancing

We have managed the world's largest and longest running vibration analysis programs.

-

Laser Alignment

We have managed the world's largest and longest running vibration analysis programs.

-

360° Maintenance

We have managed the world's largest and longest running vibration analysis programs.

-

Trainings

We have managed the world's largest and longest running vibration analysis programs.

-

Information & Knowledge

We have managed the world's largest and longest running vibration analysis programs.